Unionpack, as a professional overseas sales and service team for REZPACK who is one of China’s preeminent packaging machinery manufacturers, with more than two decades of experience in packaging machinery industry, our machine have been delivered to over

3000 companies in 30 countries. Our partners and technical consultants can be found in Europe, America and Southeast Asia, bringing us techniques and expertise from all over the world. Rezpack is certified to ISO9001 and CE standards,

and have obtained more than 200 patents.

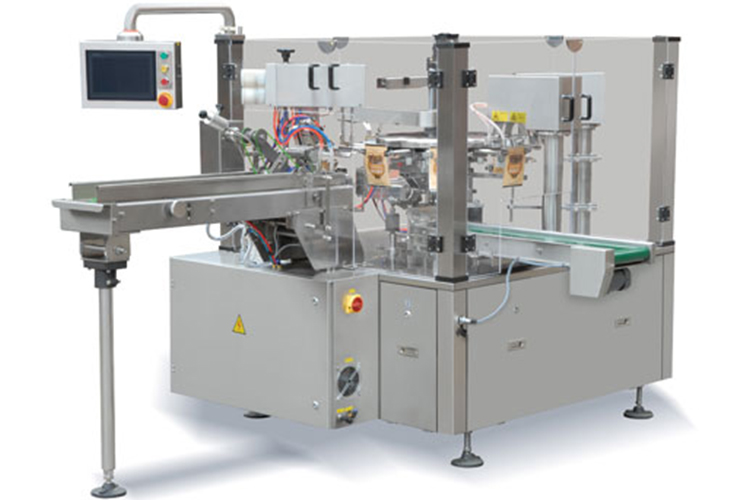

PFS / Pouch Packaging Machine

Application

-

Solid: leisure food(candy chocolate)etc.

-

Grain: condiment(monosodium glutamate, chicken essence, granulated sugar) dry fruit (nuts), capsule,grain medicine, seed, feed etc.

-

Powder: condiment, monosodium glutamate, salt, glucose,narrowly sugar, milk powder, washing powder etc.

-

Liquid: yellow wine, soy sauce, rice juice, drink, detergent etc.

-

Thick liquid: ketchup, peanut butter, sauce, chill sauce, bean butter etc.

Bag Type

Standup bag, Doypack.

Selectable Auxiliary Equipment

-

Liquid filler

-

Multi-head Computer Weigher

-

Conveyor

-

Working Platform

-

Auger Filler

Station Process

-

Bag Feeding

-

Date Coding + Bag Opening

-

Filling + Bag Bottom Opening

-

Tray Vibrating

-

Standby (can add functions of filling liquid, air exhausting, dust cleaning etc.)

-

Heat Sealing 1

-

Heat Sealing 2 or Forming

-

Output

Main Technical Parameters

| Equipment Model |

RZ8-200D |

| Bag Size |

W:70~200mm L:100~300mm |

| Filling Range |

5~1500g |

| Packing Speed |

20~50 Bags/min |

| Weight |

1200kg |

| Dimension |

1570mm * 1440mm * 1480mm (L,W,H) |

| Total power |

3kw |

Main Features

-

Wide applications: various shapes, state and nature of products (such as rice, coarse grains, nuts, spicy snack, Chinese chestnut liquid, etc.)

-

Easy to operate: PLC controller, HMI system makes easy operation.

-

Easy to adjust: Synchronously adjust machine clamp, and parameters for different products can be saved and available from database when changing products.

-

High Automation: Complete all actions by grooved clamp,which is more durable than end cam, and it do not need springs to return,more stable in running.

-

Perfect Prevention System: when the bag is not open or not opened enough, it will be non-filling and non-sealing, so the empty bags return to the first station to refill and not wasted and it will save the production cost.

-

Stainless steel/other materials ensure sanitation and safety, meet the GMP standard.

-

Oil-free vacuum pump: avoid production environment pollution.

-

Waterproof Design: direct water-washing the machine surface, easy to clean, prolong the useful life.

-

Premade bag packing: high sealing quality, upgrade the finished product.

-

Adopt concentrated oil-supplied lubrication device inside the grooved cam. (Machine clamps are adjusted in one time, mechanical actions are controlled by grooved cam, empty bag cycling, product parameters can be saved)